Developed from Practical Experience

With over 10 years of experience in industrial maintenance and as a certified Industrial Master Metalworking, I know the challenges that maintenance teams face daily.

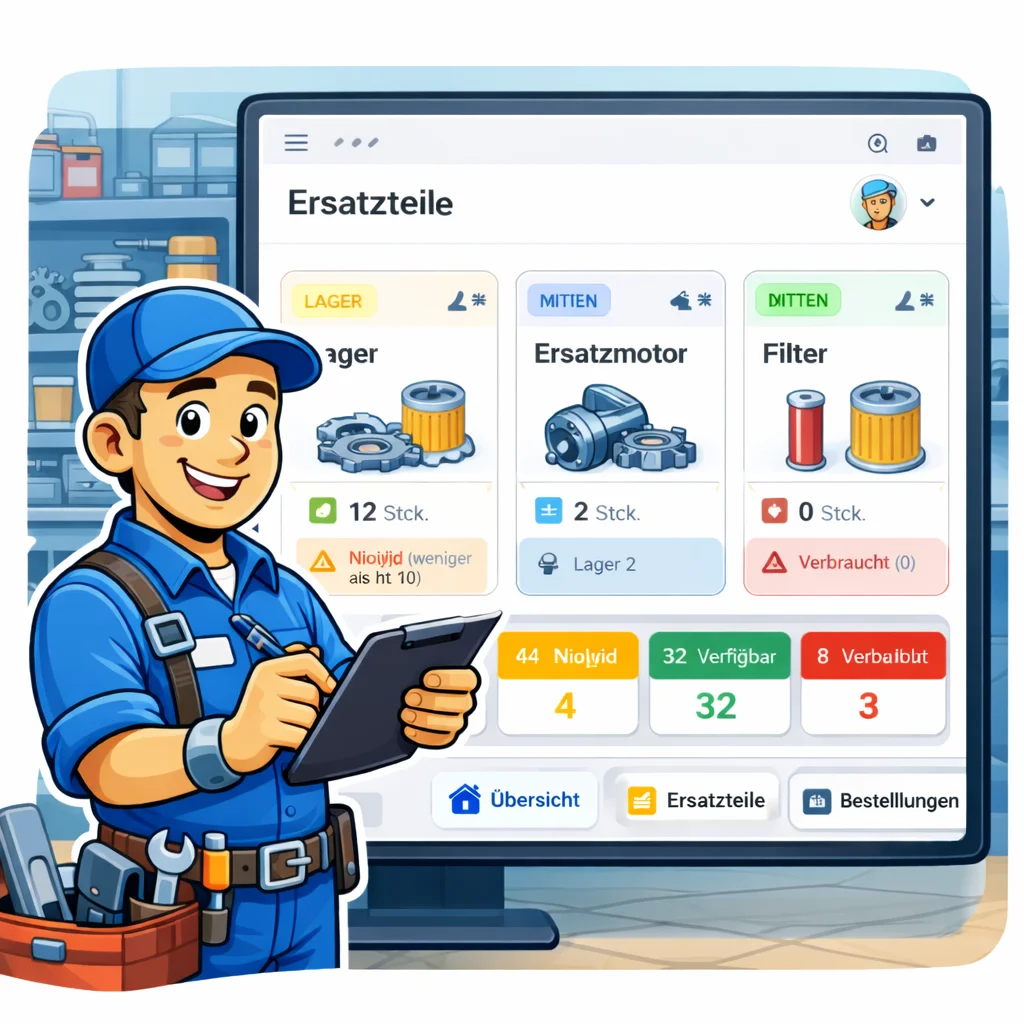

I know exactly what matters – and where things go wrong. My goal: a tool that digitalizes maintenance processes simply and practically.

"Simplicity and practicality come first.

Software is only useful if it's actually used."

- Iwan Gerber, Industrial Master Metalworking